VINEYARD UPDATE

Cooler than normal temperatures and a persistent layer of fog have blanketed the North Coast of California, over the past two weeks. With temperatures struggling to get into the 80s, our grapevines are literally “chilling out.” The lack of temperatures in the 90s or 100s has many benefits at this time of year, and will only become a concern if September’s weather continues to be as cool as August’s.

As a Pinot Noir winemaker in California, I certainly prefer this cool pattern, to one with clear skies and soaring temperatures. The biggest advantage is increased “hang time,” before we choose to harvest the grapes. In some years, we experience late August or early September temperatures, as high as 114 degrees Fahrenheit! This results in very rapid sugar concentration in the berries and requires us to harvest rapidly to avoid dehydrating the grapes. We’re not interested in producing raisins from our Russian River Valley Pinot Noir grapes, even though they’d be amazing!

Despite our anxiousness to get harvest underway, expected pick-dates are still in the “normal” range, in historical terms, with the first Pinot Noir grapes likely to come into the winery around September 5. It may start slowly, but soon a flood of Pinot Noir will be passing across the sorting table, on the way to our open top fermenters.

SAMPLING FOR RIPENESS

As harvest nears, I have a long list of vineyard blocks that need repeated visits. Early in the season, my visits were to monitor visual condition of the grapevines and connect with our grape growers. Overall health of the vines, lack of disease or insect damage, and the quantity of grapes hanging on the vines were all checked regularly. If the crop level was too high to effectively ripen the grapes, pruning to thin the crop was performed.

Now, as we approach harvest, visits become sampling events. Grape clusters are cut from the vines throughout each block, to provide a representation of the ripeness of the entire block. These clusters are then “crushed” by hand, to break the berries open and release the juice. We will also macerate the skins somewhat as we crush the berries, allowing color pigments and tannins to escape from the skin cells. The fresh juice is strained from the skins, seeds, and stems, and collected in beakers.

In the lab, we use a few tools to analyze the juice. The refractometer gives us an accurate reading for brix, or sugar concentration.

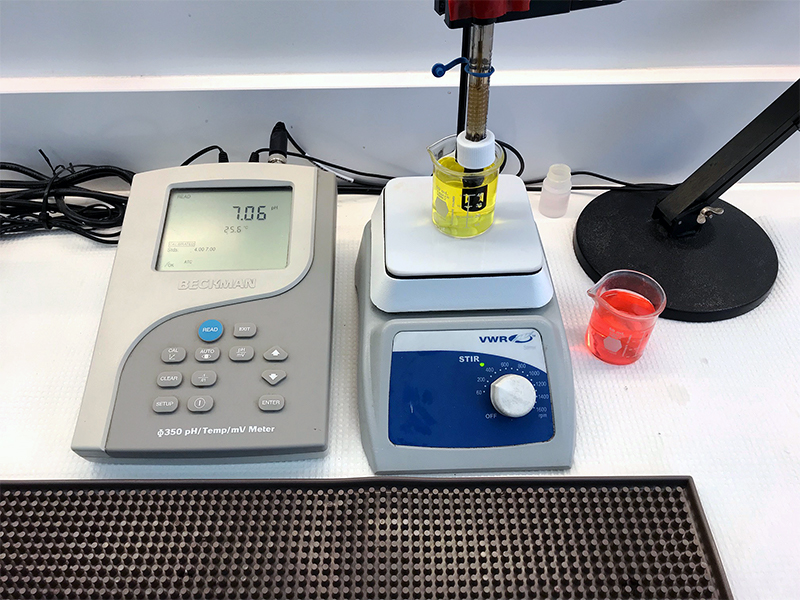

A benchtop pH meter provides precise pH levels, a critical measurement for determining yeast and bacterial viability in the juice.

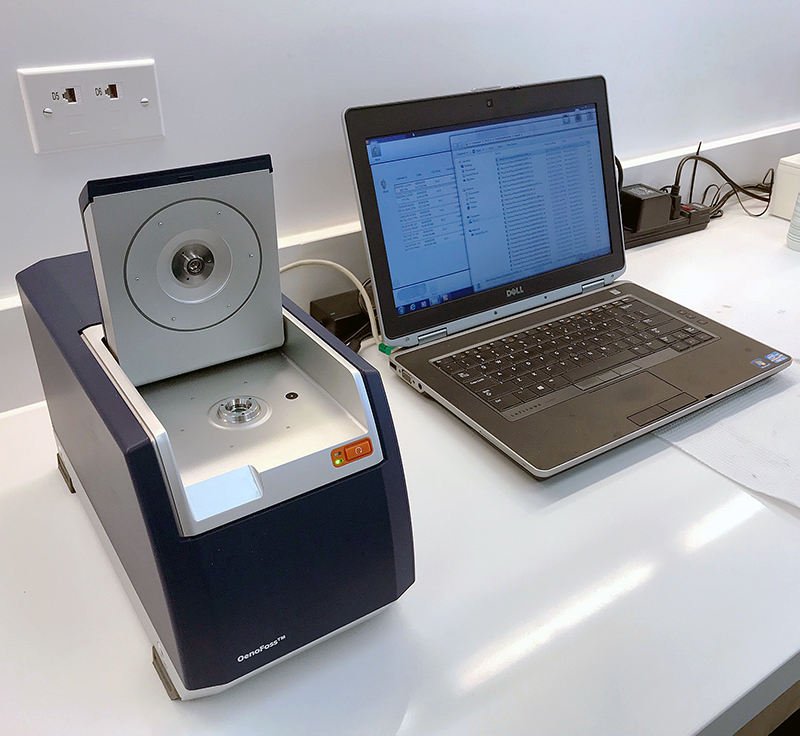

The most important piece of lab equipment at Ron Rubin Winery is our OenoFoss analyzer, which can give us the following analyses from a single tiny sample:

- YAN: The total nitrogen available to the yeast during fermentation (YAN is comprised of both ammonia and free amino nitrogen)

- Malic and Tartaric Acid: The two most important acids found in grape juice

- VA: An indicator of spoilage, possibly due to bird or insect damage to the grapes

These analyses give us a window into the condition of the grapes, and provide guidance on harvesting and fermentation.

We’ll be sampling every vineyard and every block repeatedly, as each harvest date approaches. In watching trends (especially increasing sugar levels, decreasing acidity, and increasing color extraction), we’ll be able to schedule picking dates, to maximize the potential of each block. Once harvest begins, I’ll be sure to document the highlights and share them with you in October’s Winemaking Notes!

ED’S COOPER NOTES

August is behind us, and we’re rapidly approaching Harvest 2018! All our barrels are empty and are eagerly awaiting to be filled with the new vintage. In addition to vineyard checks and prepping the crush pad to receive grapes, we’re receiving our new, 2018 barrels.

There’re many facets to winemaking we’re constantly managing. From all of them, the marriage of wood and wine is truly a remarkable one. Oak barrels hold a special place in our wine cellar. Using oak barrels to elevate wine is an age-old process, steeped in tradition. Barrels have the ability to infuse wonderful flavors, textures, and aromas into wine. It’s no wonder why most of today’s world class wines are aged in oak barrels. The most widely used types of barrels are made from French and American oak. The biggest differences between the two are aromatic intensity and texture contribution.

- French oak typically is subtler in both aromatics and flavors, it’s spicier, and has more oak tannins, so you get a firm mouth feel and mid-palate weight from it.

- American Oak has bolder aromatics and flavors. You get a great fragrant profile; think bacon covered in maple syrup! Texturally it’s softer and creamier, because it doesn’t have much oak tannin.

At Ron Rubin Winery, we approach our barrel usage the same way a master chef would approach using his or her spice rack – judiciously! We work with the best coopers in operation, to ensure we’re using the best “spices” available. For our Pinot Noirs, we use 100 percent French Oak, because it’s a perfect complement to the wonderful fruit grown here, in Green Valley of Russian River Valley. For our River Road Boschetti “Old Vine” Zin, we use 100 percent American Oak; not only because it’s the perfect complement to this wine’s charming, rustic character, but to also pay respect to Zinfandel’s “American heritage.” By using the best ingredients and the perfect blend of spices, we’re able to create A Beautiful Experience in every bottle we produce.

Cheers!